General Fiber Optic Inspection and Fiber Optic Cleaning Procedures

This section describes the connector cleaning process. Additional sections provide more detail on specific fiber optic inspection and fiber optic cleaning techniques.

General Cleaning Process

Complete these steps:

-

Inspect the fiber connector, component, or bulkhead with a fiber microscope.

-

If the connector is dirty, clean it with a dry cleaning technique.

-

Inspect the connector.

-

If the connector is still dirty, repeat the dry cleaning technique.

-

Inspect the connector.

-

If the connector is still dirty, clean it with a wet cleaning technique followed immediately with a dry clean in order to ensure no residue is left on the endface.

Note: Wet cleaning is not recommended for bulkheads and receptacles. Damage to equipment can occur.

-

Inspect the connector again.

-

If the contaminate still cannot be removed, repeat the cleaning procedure until the endface is clean.

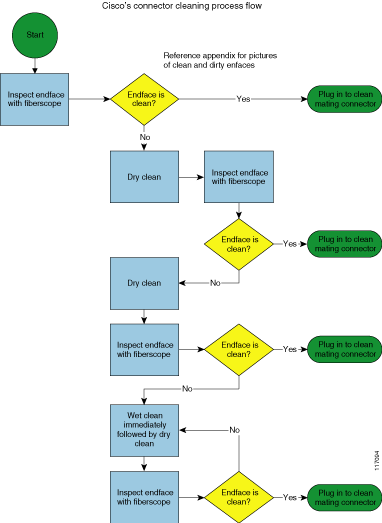

Figure 1 shows the connector cleaning process flow.

Figure 1

Note: Never use alcohol or wet cleaning without a way to ensure that it does not leave residue on the endface. It can cause equipment damage.

Connector Inspection Technique

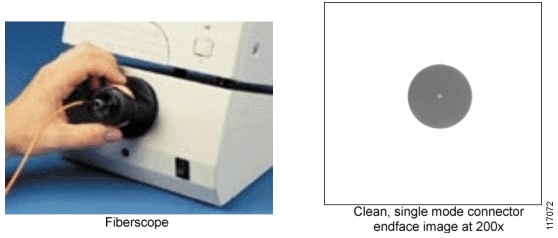

This inspection technique is done with the use of fiber microscope in order to view the endface.

A fiber microscope is a customized microscope used in order to inspect optical fiber components. The fiber microscope should provide at least 200x total magnification. Specific adapters are needed to properly inspect the endface of most connector types, for example: 1.25 mm, 2.5 mm, or APC connectors.

Tools

-

Clean, resealable container for the endcaps

-

Fiber microscope

-

Bulkhead fiber optic inspection probe

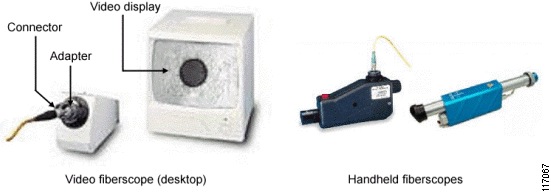

Figure 2 shows different kinds of fiber microscope

Figure 2

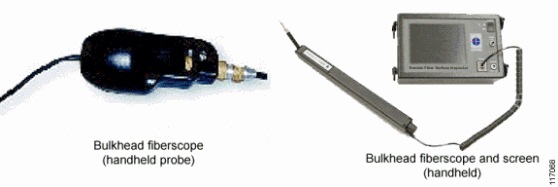

The bulkhead fiber optic inspection probe is a handheld fiber microscope used in order to inspect connectors in a bulkhead, backplane, or receptacle port. It should provide at least 200x total magnification displayed on a video monitor. Handheld portable monitors are also available. Specific adapters are needed in order to properly inspect the endface of most connector types.

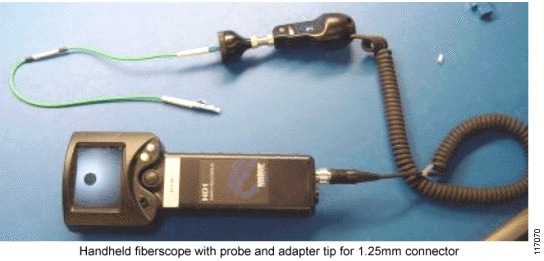

Figure 3 shows a handheld fiber microscope with probe and adapter tip for 1.25 mm connector.

Figure 3

Figure 4 shows two types of handheld fiber microscope.

Figure 4

Caution: Read the reminders and warnings before you begin this process.

Caution: Read the reminders and warnings before you begin this process.

Complete these steps in order to inspect the connector:

-

Make sure that the lasers are turned off before you begin the inspection.

Warning: Invisible laser radiation might be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments.

Warning: Invisible laser radiation might be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. -

Remove the protective cap and store it in a clean resealable container.

-

Verify the style of connector you inspect and put the appropriate inspection adapter or probe on your equipment.

-

Insert the fiber connector into the fiber optic microscope adapter, and adjust the focus ring so that you see a clear endface image. Figure 5 shows a clean single mode connector endface.

-

Or, place the tip of the handheld probe into the bulkhead connector and adjust the focus.

Figure 6 shows the handheld probe inserted into a bulkhead connection.

Figure 6

-

On the video monitor, verify that there is no contamination present on the connector endface.

-

Clean the endface and reinspect, as necessary. Refer to the appropriate section:

-

Cleaning Techniques for Pigtails and Patch Cords

-

Cleaning Techniques for Bulkheads and Receptacles

-

-

Immediately plug the clean connector into the mating clean connector in order to reduce the risk of recontamination.

Fiberopticcleanings.com stocks a variety of fiber optic cleaning supplies, from one click cleaners to fiber cleaner, from fiber optic cleaning wipes to fiber cleaning kit – everything you need for fiber optic cleaning jobs, BUY NOW and get FREE SHIPPING on most items!

Leave a Reply